Fri 29 May 2020

TASTE IS AROMA!

Posted by DrSmokeRead other related stories: Cooking , General Smoking Information

No Comments

Taste is aroma blog discusses how aroma affects our tasting sense.

TASTE IS AROMA

listen to our blog regarding wood chips for smoking

It is likely the most common question posed to us – how does the wood make the food taste? Although I have answered this question hundreds of times, it started me thinking about my answer. It was not complete. I was not explaining that taste IS aroma.

Our experiences with food revolve around our senses and of those senses 3 deal primary with food: taste, touch, and smell. Obviously, you would assume that the sense of taste is the absolute in food experience but you would be wrong. 10,000 plus different odors are relayed via our sense of smell which occurs through our nose and mouth. As much as 80% of what is referred to as taste is aroma.

Cooking smoke vapor flavors food

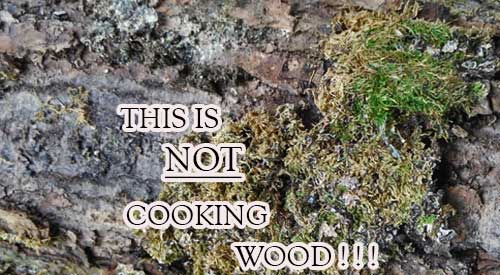

Now, apply this information to the fact that we use wood in cooking techniques that involve infusion of smoke vapor to foods and ingredients, and you will begin to understand where I am going with this. We have all had the experience of smelling a neighbor burning fallen leaves come Fall. It is not a pleasant aroma. Could you imagine someone putting food over a fire that contained leaves as fuel and then tasting the food cooked over that fuel source? Terms that come to mind include bitter, acrid, burnt, and pungent.

Taste Is Aroma- Overall Flavor is Dependent on a lot of Factors

I have my answer to the question “What kind of flavor does (insert wood type here) produce.” The overall flavor is dependent on a lot of factors. These include:

- climate and soil of where the tree is grown: the more balanced the pH level of the soil and a location that has suitable precipitation throughout the year, are more favorable to a hardwood tree’s benefit as a cooking wood

- bark or bark-free: this affects burn rate and flavor, and yes, it can fluctuate your temperature control

- moisture level: the drier the wood the faster it goes through combustion and the more heat it produces. You need some level of moisture left in the wood to produce smoke

- humidity of the cooking environment: dry cooking environments do not allow for smoke vapor to stick

- type of dry rub and/or sauce/marinade used: wood needs to be viewed as an ingredient to the entire cooking experience so ALL the ingredients need to marry to produce a great flavor. The wood is just one flavor component

- what you’re cooking (beef, turkey, pork, chicken, lamb, goat, etc.): maple used on beef will taste completely different than maple used with chicken. Plus, the type of meat/poultry also influences the flavor, so think generic versus farm raised and cage free versus free range. Just as the soil and climate affect the trees so too does the diet and climate affect the animal.

Taste Is Aroma- Flavor Guide

Although we offer a SmokinLicious® flavor guide with descriptors of the undertones the wood can produce, here is my best summary of the hardwoods we provide:

Mild: Alder, Ash, Sugar Maple, Wild Cherry

Moderate: Beech, Hickory

Strong: Oak

If you treat the wood as an ingredient you will come to appreciate all that it can offer. Now, you will be able to produce some spectacular tasting and aromatic dishes both during the cooking process and at its final stage!

Dr. Smoke- Aroma is key! Don’t forget that the wood type is just as important as what is being smoked when it comes to flavor!

SmokinLicious® products:

Wood Chunks- Double & Single Filet

Wood Chips- Minuto®

More Related reading on “What Wood for Smoking” and other great smoking and grilling tips and techniques